APD Series: 2-Bed Portable Desiccant Dryers

Industry standard desiccant dryer, hopper and optional loading systems provide easy, reliable and safe material handling by eliminating press/extruder mounted drying hoppers for fast material changes.

System Features

-

-

- Space-saving, compact design

-

- Stainless steel, insulated hoppers

-

- ADC (Advanced Dryer Control) Control is standard and includes:

-

-

- -49 F dewpoint monitor

-

- 7 day timer

-

- Diagnostic functions

- Dewpoint, heater and temperature alarms

-

-

- ADC (Advanced Dryer Control) Control is standard and includes:

-

- Closed loop loading (optional) conveys dried material with dry air

- Available power: 208, 230, 400, 480, 600 VAC; 50/60 Hz

-

Energy efficiency:

-

-

- Most energy efficient dryer in the market (when compared to compressed air, rotary

wheel, vacuum and other dual bed dryers)

- Most energy efficient dryer in the market (when compared to compressed air, rotary

-

- Temperature based regeneration; adapts to ambient and material conditions

- Single blower design will save up to 50% in energy costs

-

Reliable 2-bed operation offers:

-

-

- Dew points as low as -49ºF

- No moving parts

-

Standard benefits:

-

-

- Stainless steel hoppers have laser-cut access doors which eliminate troublesome gaskets

-

- Full-flo electric valve for bed switchover eliminates compressed air

-

- Compact design saves valuable floor space

- Convenient handle allows for easy mobility

-

| Dri-Air Model | Process Rate | Hopper Capacity | Dimensions | |||

| (lbs/hr) | (kg/hr) | (lbs) | (kg) | [l/w/h] inch | [l/w/h] cm | |

| APD-1 | 7.5 | 5 | 30 | 14 | 25/39/57 | 64/99/145 |

| APD-2 | 15 | 7 | 60 | 27 | 25/39/62 | 64/99/169 |

| APD-3 | 25 | 12 | 100 | 45 | 25/39/60 | 64/99/152 |

| APD-4 | 35 | 16 | 150 | 68 | 25/39/73 | 64/99/185 |

| APD-5 | 40 | 20 | 150 | 68 | 30/52/75 | 76/152/191 |

| APD-6 | 50 | 25 | 200 | 91 | 30/52/69 | 76/152/175 |

| APD-7 | 75 | 35 | 300 | 136 | 30/52/84 | 76/152/213 |

| APD-8 | 90 | 45 | 300 | 136 | 30/52/84 | 76/152/213 |

| APD-9 | 110 | 45 | 400 | 181 | 50/42/92 | 127/107/234 |

| APD-10 | 150 | 68 | 600 | 272 | 50/42/112 | 127/107/284 |

| APD-11 | 200 | 91 | 600 | 272 | 50/42/112 | 127/107/284 |

HPD Series: 4-Bed Portable Desiccant Dryers

Patented, high performance dryer, drying hopper and optional loading systems. DRI-AIR’s PD Series eliminates press/extruder mounted drying hoppers for fast, safe material changes.

System Features:

-

-

- Space-saving, compact design

-

- Stainless steel, insulated hoppers

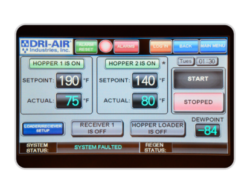

- Smarttouch Control features:

-

-

- Industry 4.0 ready

-

- Ethernet or WIFI communication options

-

- OPC/UA open platform

-

- -49 F Dewpoint Monitor

-

- 7 day timer

-

- Buildable resin library

- Prevent over drying with optional temperature set back

-

-

-

-

-

- Closed loop loading (optional) conveys dried material with dry air

- Available power: 208, 230, 400, 480, 600 VAC; 50/60 Hz

-

Energy efficiency:

-

-

- Most energy efficient dryer in the market (when compared to compressed air, rotary wheel, vacuum and other dual bed dryers)

-

- Temperature based regeneration; adapts to ambient and material conditions

-

- Single blower design will save up to 50% in energy costs

- Temperature setback (optional) reduces drying temperature when material is dry

-

Exclusive high performance 4-bed operation offers:

-

-

- Faster drying of materials

-

- Dew points as low as -130ºF

- No moving parts

-

Applications:

-

-

- Medical molding

-

- Optical grade molding; lens & CD/DVD

- Tough to dry materials

-

Conditions:

-

-

- Relative humidity over 80%

- Non-air conditioned facilities

-

| Dri-Air Model | Process Rate | Hopper Capacity | Dimensions | |||

| (lbs/hr) | (kg/hr) | (lbs) | (kg) | [l/w/h] inch | [l/w/h] cm | |

| HPD-1 | 10 | 6 | 30 | 14 | 25/39/57 | 64/99/145 |

| HPD-2 | 20 | 10 | 60 | 27 | 25/39/62 | 64/99/169 |

| HPD-3 | 30 | 14 | 100 | 45 | 25/39/60 | 64/99/152 |

| HPD-4 | 40 | 18 | 150 | 68 | 25/39/73 | 64/99/185 |

| HPD-5 | 50 | 25 | 150 | 68 | 30/52/75 | 76/152/191 |

| HPD-6 | 60 | 27 | 200 | 91 | 30/52/69 | 76/152/175 |

| HPD-7 | 80 | 36 | 300 | 136 | 30/52/84 | 76/152/213 |

| HPD-8 | 100 | 45 | 300 | 136 | 30/52/84 | 76/152/213 |

| HPD-9 | 125 | 50 | 400 | 181 | 50/42/92 | 127/107/234 |

| HPD-10 | 160 | 73 | 600 | 272 | 50/42/112 | 127/107/284 |

| HPD-11 | 220 | 100 | 600 | 272 | 50/42/112 | 127/107/284 |

| HPD-13 | 300 | 150 | 1000 | 453 | 66/42/116 | 167/107/29 |